How to Inspect and Decontaminate Seaplane: Seaplanes capture the spirit of adventure, offering unparalleled access to America’s lakes, rivers, and coastal waterways. But this freedom of flight over water carries with it serious responsibilities. The critical task of inspecting and decontaminating seaplane rudders, cables, and internal compartments plays a huge role in keeping your aircraft in peak condition and protecting the environment from the spread of harmful invasive species. This article unpacks this hidden threat with friendly yet authoritative guidance, blending practical advice with expert insights suitable for both beginners and seasoned pros.

Table of Contents

How to Inspect and Decontaminate Seaplane?

Seaplane pilots are frontline custodians of our waterways. Effective inspection and decontamination of rudders, cables, and internal compartments not only prevent the spread of invasive species but also extend your aircraft’s lifespan and safety. Make inspection and cleaning part of your pre- and post-flight routine. You’re not just preserving your seaplane; you’re protecting the natural heritage of lakes, rivers, and coastal waters millions rely on for recreation and livelihood. Fly smart, fly safe—and keep our waters pristine for the generations to come.

| Topic | Details |

|---|---|

| Areas to Inspect | Rudders, cables, floats, internal compartments including bilges |

| Common Contaminants | Aquatic plants, invasive mussels, mud, algae, waterborne debris |

| Recommended Cleaning Method | Hot water wash (minimum 140°F), manual debris removal, thorough drying |

| Effective Hot Water Exposure | 10-130 seconds based on component sensitivity |

| Inspection Timing | Before and after every water landing |

| Additional Best Practices | Use detailed inspection checklists, follow FAA and environmental agency recommendations |

| Resources for Reference | EPA Aquatic Invasive Species, FAA Seaplane Safety |

Why Inspect and Decontaminate Seaplane Matter?

Flying on water subjects your seaplane to unique risks not faced by land-only aircraft. One of the biggest risks comes from aquatic invasive species (AIS)—non-native plants and critters that latch onto your aircraft and spread to new ecosystems. Once introduced, species like zebra mussels or Eurasian watermilfoil rapidly multiply, choking native vegetation and disrupting fishing and recreation.

But AIS isn’t the only concern. Mud, algae, and water can collect in rudder housings, cables, and internal compartments, causing corrosion and mechanical wear that compromise your plane’s control systems and safety.

By routinely inspecting and thoroughly decontaminating your seaplane’s critical parts, you reduce:

- The environmental impact caused by spreading invasive species

- Potential safety hazards from corrosion or debris-induced mechanical failures

- Unexpected maintenance costs and downtime due to neglected contamination

Maintaining this vigilance is a key part of a pilot’s responsibility—protecting your plane and the pristine waters you love.

Anatomy of Vulnerable Seaplane Parts

Knowing the vulnerable parts is half the battle in inspection.

- Rudders: These pivotal control surfaces attached at the rear of floats guide your seaplane’s direction on water. Being immersed frequently, they attract unwanted aquatic debris, organic growth, and are subject to corrosion.

- Cables and Control Linkages: These vital connections translate pilot inputs into rudder movements. Any fraying, rust, or stiff spots directly affect airplane handling and demand close attention.

- Internal Compartments and Bilges: Designed to keep the aircraft buoyant and house equipment, these compartments often trap water and sediment, creating prime habitats for invasive species and rust development.

Step-By-Step Inspect and Decontaminate Seaplane Process

Step 1: Detailed Visual and Physical Inspection

Start with a thorough walk-around, paying extra attention to limited viewpoint areas and right angles where dirt and plants cluster.

- Look methodically for mud, plant fragments, algae, and small animals. Use a flashlight and your hands to search crevices.

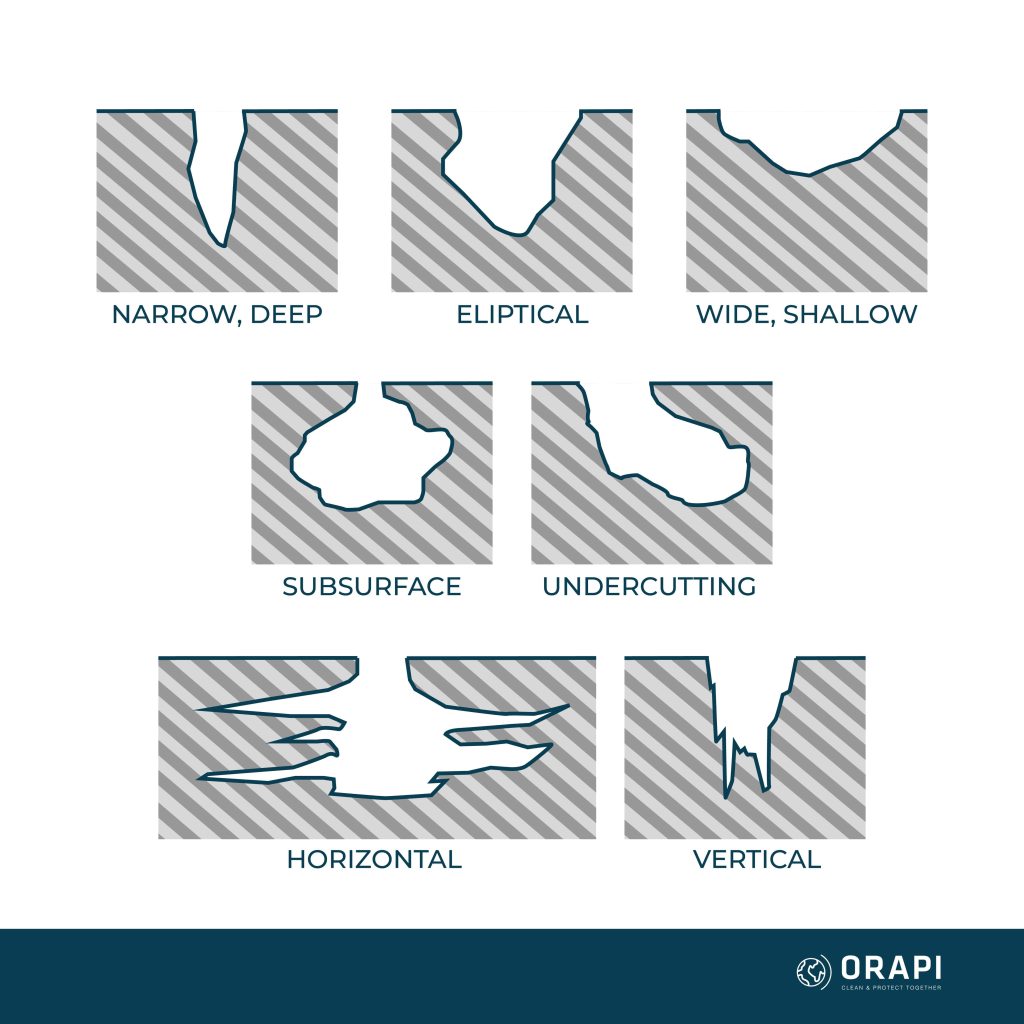

- Check for corrosion, cracks, dents, or blisters on rudders and floats.

- Test cables by moving them to detect stiffness or binding; look for visible rust or fraying.

- Remove all visible contaminants with brushes or gentle scraping. Plant fragments not removed can regrow within days.

Step 2: Drain All Water Retention Points

Seaplanes commonly retain water in compartments and bilges, which can conceal invasive species.

- Remove drain plugs and pump out any water using bilge pumps or absorbent towels.

- Thoroughly flood and flush compartments to ensure no water or debris remain.

- Look in compartments carefully for any signs of aquatic life—early detection can prevent larger infestations.

Step 3: Hot Water Cleaning and Rinsing

Hot water is the leading method to kill organisms safely and efficiently.

- Use water heated to at least 140°F (60°C) to flush rudders, floats, cables, and internal areas.

- Spray water from around 4-12 inches away at medium pressure to remove contaminants without damaging surfaces.

- For internal compartments, allow water contact for 90-130 seconds to ensure invasive species are effectively neutralized.

- Follow manufacturer guidelines closely to prevent damaging paint or materials.

- Avoid chemical disinfectants that may harm the environment or your aircraft.

Step 4: Thorough Drying Procedures

After cleaning, drying is critical to prevent rust and further contamination.

- Open all compartments and leave drain plugs off to maximize air circulation.

- Park your seaplane in sunny, breezy locations when possible.

- Use absorbent towels and air blowers for hard-to-dry areas.

- Remember: moisture left inside compartments or behind cables fosters corrosion and invasive species growth.

Step 5: Documentation and Reporting

Tracking your efforts is vital for regulatory compliance and environmental stewardship.

- Maintain detailed inspection and cleaning records including dates, findings, and actions.

- Report any invasive species detected to local environmental or fisheries authorities.

- Use FAA maintenance records to align with recommended inspection intervals and preserve aircraft value.

Common Threats and Their Impact

Aquatic Invasive Species (AIS)

Non-native species are a widespread problem in U.S. waterways. They outcompete native organisms, clog boat motors, foul fishing gear, and destroy fish habitats. AIS such as zebra mussels stick to surfaces and grow quickly if untreated; Eurasian watermilfoil chokes recreational areas.

Seaplanes operating across different regions risk spreading these threats rapidly if not inspected and decontaminated properly.

Corrosion and Mechanical Failure

Water trapped in internal spaces creates rust hotspots that degrade metal rudder stocks, cable sheaves, and connection points. Corroded control cables risk snapping or sticking mid-flight—a safety hazard no pilot wants to encounter.

Advanced Maintenance Insights for Professionals

Pilots and maintenance teams can enhance routine efforts with these proven strategies:

- Adopt manufacturer-specific inspection checklists focusing on recommended inspection intervals.

- Use tools such as borescopes and endoscopes for internal compartment inspections where visibility is limited.

- Conduct functional checks of the rudder system after cleaning, ensuring smooth operation without slack or binding.

- Apply corrosion-resistant lubricants on cables and fasteners following cleaning.

- Train crew regularly on aquatic invasive species (AIS) risks and mitigation techniques.

- Follow FAA Advisory Circulars such as FAA-H-8083-23 for comprehensive seaplane operational safety.

Expert Tips to Keep Your Seaplane Pristine

- Never rely solely on water rinses—scrubbing floats and rudders removes stubborn algae and plant fragments.

- Inspect cables regularly to detect fraying early and lubricate to prevent rust.

- Avoid landing in shallow, weed-filled waters where AIS thrives.

- Keep rudders retracted when operating in shallow or debris-prone areas to avoid damage.

- Document and inspect after every flight, especially when moving between water bodies.

- Educate all pilots and handlers on the importance of the Clean, Drain, Dry routine.

Beyond the Boat: Why Seaplane-Specific Decontamination Is Different

Decontamination Deep Dive: Hot Water vs. High Pressure for Floats and Rudders

(White Paper) Closing the Seaplane Pathway: A Digital Strategy for State Regulators