How Technology Can Solve the Seaplane Inspection Gap: Seaplanes are one of those unique American aviation gems that land and take off on water, connecting remote lakes, rivers, and coastal spots to the rest of the world. But here’s the kicker—inspecting these beauties is trickier than your everyday plane inspection since they’re constantly soaked, often far from proper inspection facilities. The question stands: how do we bridge the seaplane inspection gap beyond the classic boat ramp setting? Technology is stepping up big time to make these inspections safer, smarter, and cleaner in 2025. Seaplanes face special challenges when it comes to inspections. Their floats and hulls get beaten up by water, corrosion, and creeping aquatic invasive species (AIS). For pilots and maintenance crews, getting a good look at those parts can be a pain—especially at lakes and rivers where there’s no dock or hoist. But with cutting-edge tech like drones, AI, sensors, and DNA scanning coming into play, the seaplane world is turning the tide in its favor.

Table of Contents

How Technology Can Solve the Seaplane

Seaplanes hold a special place in the American aviation landscape, offering unparalleled access to remote and scenic locations. But the water they float on challenges traditional inspection practices, putting safety, environmental health, and maintenance effectiveness at risk. Thanks to innovative technology like underwater drones, AI-powered analysis, connected sensors, autonomous robots, and DNA-based AIS detection, the gap beyond the boat ramp is closing fast. These tools help pilots fly safer, protect precious water bodies from invasive species, and support a thriving seaplane industry that’s growing in economic and environmental importance. As seaplane technology evolves, so does the promise of smarter inspections, greener operations, and a richer future for water-borne flight. Inspection Gap

| Topic | Details |

|---|---|

| Inspection challenges | Difficult float/hull access, water-induced wear, AIS contamination risk |

| Common issues | Corrosion, structural damage, biofouling, AIS spread |

| New technologies | Underwater drones, AI-powered image analysis, connected sensors, autonomous inspection robots |

| Benefits | Improved inspection accuracy, reduced human error, better AIS control |

| Regulations & guidelines | FAA AC 91-69A gives seaplane inspection protocols; AIS prevention is an evolving regulatory focus |

| AIS detection advancements | DNA-based environmental monitoring, remote sensing, real-time data sharing |

| Safety stats (US) | From 2008-2022, 406 seaplane accidents (77 fatal); safety improving but vigilance vital (AOPA data) |

| Economic impact (US) | U.S. seaplane industry growing with $277.55M market in 2024, projected CAGR 6.8% through 2032 |

| Future trends | Electric propulsion, urban air mobility, autonomous seaplanes, advanced aerodynamics, and lightweight materials |

| Career relevance | Aviation maintenance, drone operation, environmental monitoring, and AI technician roles expanding |

| Official Source | FAA AC 91-69A Seaplane Safety |

What Makes Seaplane Inspections Unique?

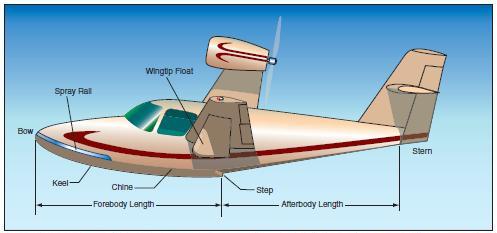

Unlike your standard aircraft, seaplanes live on the water. Their floats and hulls get hammered regularly by waves, saltwater, algae, and sometimes uninvited guests like zebra mussels or invasive plants. This exposure makes these aircraft more susceptible to corrosion, cracks, material fatigue, and biofouling than land planes. Inspectors need to eyeball these parts while the plane is still floating, often at docks or boat ramps with limited infrastructure.

Inspecting the airframe on water is complicated because the seaplane has to be carefully repositioned to access all parts safely. For example, checking the hull’s underside or float compartments requires maneuvering since they are partly submerged. On the other hand, preflighting a seaplane on land introduces challenges like wings and tail surfaces being hard to reach without special equipment. This increases the risk of missed defects.

Unlike land planes, seaplane inspection must also consider the integrity of watertight float compartments, which can fill with water unnoticed, potentially affecting payload and flight safety. Water intrusion can go unnoticed without diligent bilge checks and plug inspections, given the pressure and stresses from takeoffs and landings.

The Traditional Inspection Process: Challenges & Limitations

A traditional preflight inspection includes many standard checks shared with land planes, like oil and fuel levels or control surface movements. However, seaplane inspections add many water-specific steps that complicate the process:

- Float and Hull Damage: Inspectors look for dents, cracks, loose rivets, or deep scratches, paying close attention to stress points like welds and chines (the hull’s sharp angles that meet the water).

- Corrosion Checks: Saltwater exposure can corrode metal fittings and fasteners quickly. These parts demand regular attention, especially the spreader bars, bracing wires, and water rudder mechanisms.

- Biofouling and Debris: Inspectors must remove algae, aquatic plants, or small animals lodged in rudders, water rudder assemblies, or the bilge, which affect maneuverability and safety.

- Water Rudder Mechanism: The water rudder and its cables require special inspection for stiffness, binding, or damage, since they steer the seaplane on water.

- Bilge Pumps and Water Drainage: Inspectors must operate bilge pumps to remove standing water and check for leaks inside float compartments. Damage is often hidden behind inspection plates, which must be removed and replaced carefully.

- Ice Build-up: In colder climates, ice in float compartments or on water rudders can pose risks untreated during inspections.

These inspections are physically demanding, time-consuming, and sometimes dangerous, especially on uneven docks or rough waters. The chance of human error increases when inspectors can’t thoroughly access all areas, emphasizing the need for improved technology.

How Technology Can Solve the Seaplane Inspection Gap

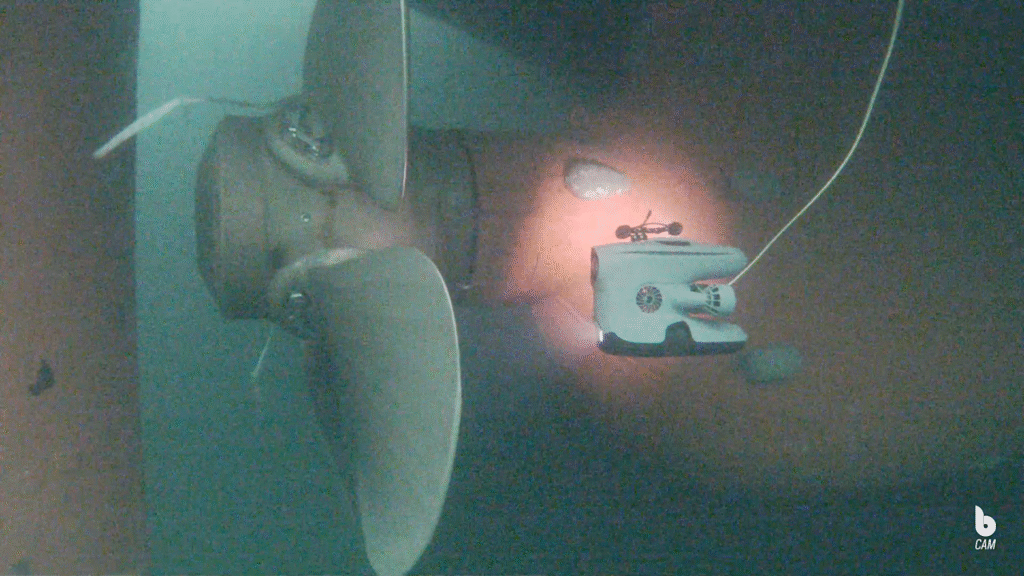

1. Underwater and Surface Drones

Drones specialized for underwater operations can maneuver closely around a seaplane’s floats and hulls, capturing high-resolution 3D images and videos. Their agility means they inspect hard-to-reach places like chines, skegs, and rudders without needing to haul the plane out.

Surface drones scan the hull above waterline, while underwater variants check below with sonar and optical sensors. Quicker and safer than manual inspections, drones reduce downtime and enhance inspection accuracy.

2. AI-Powered Inspection

AI algorithms analyze drone footage and images to identify early signs of corrosion, cracks, and biofouling that might be missed by human eyes—even experienced inspectors. Machine learning models trained on thousands of seaplane images can detect subtle material fatigue or rivet loosening with high precision.

AI-powered inspections shorten the report turnaround time, enabling faster maintenance responses and reducing the risk of in-flight failures caused by missed defects.

3. Connected Aircraft Sensors

Embedded stress sensors and environmental monitors continuously track structural integrity, saltwater exposure, and component wear. When anomalies appear—like unexpected vibrations or corrosion levels—pilots and mechanics receive real-time alerts via Electronic Flight Bags (EFBs) or mobile devices, allowing for proactive inspections before flight.

This shift from reactive to predictive maintenance means fewer unexpected repairs and improved safety margins.

4. Autonomous Inspection Robots

These sophisticated waterborne robots autonomously navigate around seaplanes, scanning the hull and floats using sonar, visual cameras, and lidar. Cloud connectivity uploads detailed reports for maintenance teams to analyze remotely, beneficial for operators with limited inspection personnel or when seaplanes operate in remote areas.

5. DNA-Based Aquatic Invasive Species Detection

Environmental DNA (eDNA) tools detect minute traces of invasive species from water or hull swabs, often before visible infestation occurs. Rapid field kits and lab analysis help authorities and seaplane operators enforce AIS regulations, instructing cleaning and decontamination when necessary to avoid ecological damage.

Breaking Down the Inspection Process in 6 Simple Steps

- Preflight Visual Checks: Using drones or cameras, pilots or inspectors gather high-res images of floats and hulls, focusing on dents, corrosion spots, water plugs, and rudders.

- AI-Powered Analysis: Images are processed with AI tools highlighting areas of concern, such as fatigue cracks or biofouling.

- Aquatic Invasive Species (AIS) Testing: Water and hull swab samples are analyzed via DNA or environmental testing to detect invasive species presence. Positive hits trigger decontamination protocols.

- Hands-On Physical Checks: Inspectors verify cables, bracing wires, rudders, and bilge compartments, cross-referencing sensor data with tactile inspection to confirm flagged issues.

- Maintenance Actions: Any defects or contaminants identified are fixed or cleaned by maintenance personnel, either on-site or by removing the aircraft from the water.

- Digital Documentation: All inspection results, maintenance repairs, and AIS logs are recorded electronically in EFBs or cloud platforms, facilitating compliance with FAA regulations and environmental agencies.

This system combines human expertise, smart technology, and environmental stewardship into a robust framework ensuring seaplane safety and sustainability.

Why This Matters: Safety, Environment, and the Bottom Line

Between 2008 and 2022, the U.S. recorded 406 seaplane accidents, with 77 involving fatalities. While seaplanes compose a smaller fraction of the aviation fleet, the stakes are high. Safety improvements are tightly linked to more effective inspections, reducing risks related to waterborne wear, unseen cracks, or fouled control systems [AOPA, 2023].

Economically, the seaplane market was valued around $277.55 million in 2024 and is estimated to grow annually by nearly 7% through 2032, driven by tourism, urban mobility initiatives, and more recreational users [MarketsandData, 2024]. Operators like Harbour Air are pioneering fleets featuring electric seaplanes with integrated sensor networks and smart inspections, setting a new industry standard [Harbour Air, 2025].

Environmental impacts focus on controlling AIS, which can devastate native aquatic ecosystems, fisheries, and recreational waters. Zebra mussels alone cause billions in damage and control costs annually. Early detection linked to inspection is crucial for preventing spread, helping regulatory authorities enforce decontamination and cleaning protocols with minimal disruption.

The Future of Seaplane Technology and Inspection

Looking ahead, seaplane innovation is accelerating alongside broader aviation trends:

- Electric propulsion: quieter, zero-emission flights lessen noise and environmental footprints in fragile areas.

- Urban air mobility integration: amphibious aircraft could become part of city transit networks, linking waterways and urban hubs.

- Autonomous systems: from pilotless flights to self-monitoring diagnostics, autonomy increases safety and operational efficiency.

- Advanced materials: composites and biomimetic designs improve resistance to water wear and decrease maintenance needs.

- Continuous health monitoring: future seaplanes may feature full sensor suites with AI-driven predictive maintenance forecasting component health in real time.

This technological evolution promises safer, greener, and more efficient waterborne flight operations, ensuring seaplanes remain a vital transportation mode.

State-by-State AIS Regulations: A Seaplane Pilot’s Compliance Guide

![Case Study How [Lake Association] Partners with Pilots to Stop AIS](https://seaplanesandais.com/wp-content/uploads/2025/11/Case-Study-How-Lake-Association-Partners-with-Pilots-to-Stop-AIS-300x169.jpg)