Why Seaplane-Specific Decontamination Is Different: When you think of cleaning boats, you probably picture a sponge, some soap, and a hose. But for seaplanes, cleaning and decontamination are a whole different ballgame. Seaplane-specific decontamination goes beyond basic boat cleaning, requiring extra care to protect the aircraft’s delicate parts while preventing environmental harm. Whether you’re a pilot, seaplane operator, or just plain curious, this guide will take you through why seaplane decontamination matters, how it’s done, and why it’s not as simple as a boat wash.

Table of Contents

Why Seaplane-Specific Decontamination Is Different

Understanding and applying seaplane-specific decontamination protocols protect the aircraft, the environment, and the people who rely on them. It’s a little extra work but well worth it to keep your seaplane flying safe and clean while guarding fragile aquatic habitats from invasive species and contamination. Keeping these techniques and regulations in mind empowers pilots, operators, and maintenance teams to maintain peak condition and compliance—making every flight a safe one.

| Focus Area | Details |

|---|---|

| Seaplane vs. Boat Cleaning | Requires specialized aviation-safe cleaners and compartment water drainage |

| Materials Sensitivity | Avoids corrosion and damage using aviation-approved detergents and methods |

| Environmental Protection | Manages wash water runoff responsibly to protect waterbodies |

| Cleaning Techniques | Includes low-pressure rinsing, microfiber cloth use, and advanced cabin air filtration |

| Aerodynamic & Safety Precautions | Prevents damage to sensors, rivets, and electronics by avoiding abrasive tools |

Why Does Seaplane-Specific Decontamination Matter?

Seaplanes are unique because they split their time between water and sky. This means they face challenges that neither boats nor regular airplanes do on their own. Cleaning a seaplane isn’t just about looking good; it’s about functional safety, environmental protection, and regulatory compliance.

- Functional safety: Seaplane parts like floats, hulls, and avionics are sensitive; chemical and mechanical cleaning choices directly affect their performance and longevity.

- Environmental protection: Seaplanes can unintentionally spread invasive species such as zebra mussels or aquatic plants, which devastate local waterways.

- Regulatory compliance: Aviation and environmental agencies demand rigorous cleaning standards to prevent contamination risks.

The key thing? A seaplane’s decontamination needs to balance these factors without causing damage.

Why Seaplane-Specific Decontamination Is Different?

Seaplanes aren’t just boats with wings. They’re delicate aircraft with complex systems meant to survive both water and air:

- Sensitive Materials and Electronics: Unlike boats, seaplanes feature avionics, hydrophobic sensors, and hulls coated with special paint prone to corrosion if attacked with harsh substances.

- Standing Water Risks: Seaplane hulls can trap water inside compartments, promoting corrosion and harboring invasive species if not properly drained.

- Air Filtration Needs: Seaplane cabins need regular cleaning of air filtration systems to maintain breathable air and reduce pathogen spread, a feature boats don’t have.

- Regulatory Standards: Aviation cleaning follows strict FAA and ICAO guidelines, meaning procedures are more technically demanding than typical boat wash standards.

Step-by-Step Seaplane Decontamination Guide

1. Detailed Pre-Flight Inspection

Before cleaning, inspect the seaplane for mud, algae, or debris stuck to the hull or floats. Check compartments for trapped water—leaving this in could lead to costly corrosion or biological contamination.

2. Clearing Standing Water

Drain all compartments completely using pumps, sponges, or absorbent materials. Do not leave any puddles behind. This step is critical to prevent invasive species and corrosion.

3. Choosing the Right Cleaner

Use aviation-grade detergents—these are tough on grime yet gentle on materials like fiberglass, rubber seals, and painted surfaces. Avoid standard boat soaps containing harsh chemicals or abrasives.

4. Exterior Washing: Low-Pressure & Soft Tools

Clean the exterior using low-pressure water and soft microfiber cloths or brushes to prevent scratches to the seaplane’s hull and floats. Avoid pressure washers with excessive force, which can drive water into rivets or seams.

5. Interior Cleaning and Air Decontamination

Use HEPA filtration devices and approved disinfectants inside the cabin to maintain a clean breathing environment, especially important during and after disease outbreaks like COVID-19. Cleaning instruments should avoid moisture buildup on electronics.

6. Wastewater Management

Ensure that runoff from cleaning doesn’t flow directly into lakes or rivers. Use containment mats or dedicated wash pads to prevent environmental contamination and comply with local regulations.

7. Post-Cleaning Inspection and Drying

After cleaning, perform a thorough check. Dry all areas using soft towels or air blowers, paying special attention to drainage holes and sensor covers, and look for signs of corrosion or damage you might have missed before.

Environmental Impact: Keeping It Green While Flying Clean

Seaplane operations are often praised for their low-impact transportation, especially in remote and sensitive environments. Unlike road or large fixed-wing aircraft infrastructure that requires roads or runways, seaplanes just need water to operate, reducing habitat destruction and construction.

- Modern seaplane engines, like the Pratt & Whitney turbines, are highly efficient, using refined kerosene that emits significantly less pollution compared to older piston engines.

- Seaplanes produce less noise pollution than big jets, which helps protect natural habitats and communities near popular waterways.

- However, improper decontamination and maintenance can harm water quality. For example, residual chemicals or deicing fluids, if discharged without care, have been linked to oxygen depletion in water bodies which kills fish and disrupts ecosystems.

- According to EPA studies, aircraft-related fluids when untreated can create serious water pollution issues, emphasizing the importance of responsible decontamination waste management.

Maintaining strict cleaning protocols not only protects the seaplane but ensures that waterways remain healthy and ecosystems are preserved, maintaining the balance between aviation and nature.

Why Follow Professional Seaplane Cleaning Practices?

Professional seaplane cleaning is essential because improper maintenance jeopardizes:

- Safety: Corrosion or damaged sensors can cause flight complications.

- Environmental Health: Spreading invasive species can destroy native ecosystems.

- Regulatory Standing: Violations can lead to hefty fines and grounded aircraft.

Maintaining seaplane cleanliness means longer service life, better performance, and peace of mind for pilots and passengers alike.

Real-World Examples and Data

- According to the Western Regional Panel, invasive species cause billions in damages annually by disrupting aquatic ecosystems in the U.S., making seaplane decontamination a frontline defense in these areas.

- The FAA’s Advisory Circular 20-48 outlines decontamination protocols that emphasize corrosion prevention and pathogen control tailored specifically for aircraft.

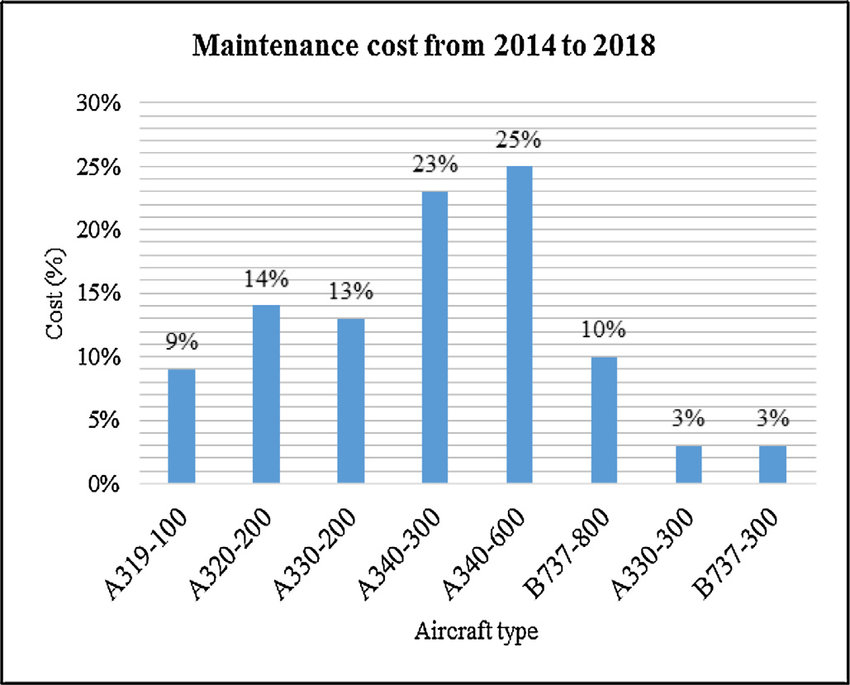

- The NBAA highlights that regular cleaning with proper agents can reduce maintenance costs by up to 20% annually and improve operational safety.

Additional Tips for Seaplane Owners and Pilots

- Schedule routine cleanings based on use, especially after water landings in new bodies of water.

- Train ground crews and operators in specialized aircraft cleaning procedures to ensure consistent maintenance.

- Document cleaning procedures meticulously to aid regulatory compliance and warranty claims.

- Use environmentally friendly products to minimize the ecological impact of cleaning operations.